TAPIS Ultrasonic Industrial Screens

TAPIS produces industrial flat screens made for installation in screening machines. We are also able to fabricate ultrasonic screens that are of a different design from TAPIS brand. The positioning of the wave-guide and sonic ring that transmits the Ultrasonic energy is critical in the frame design.

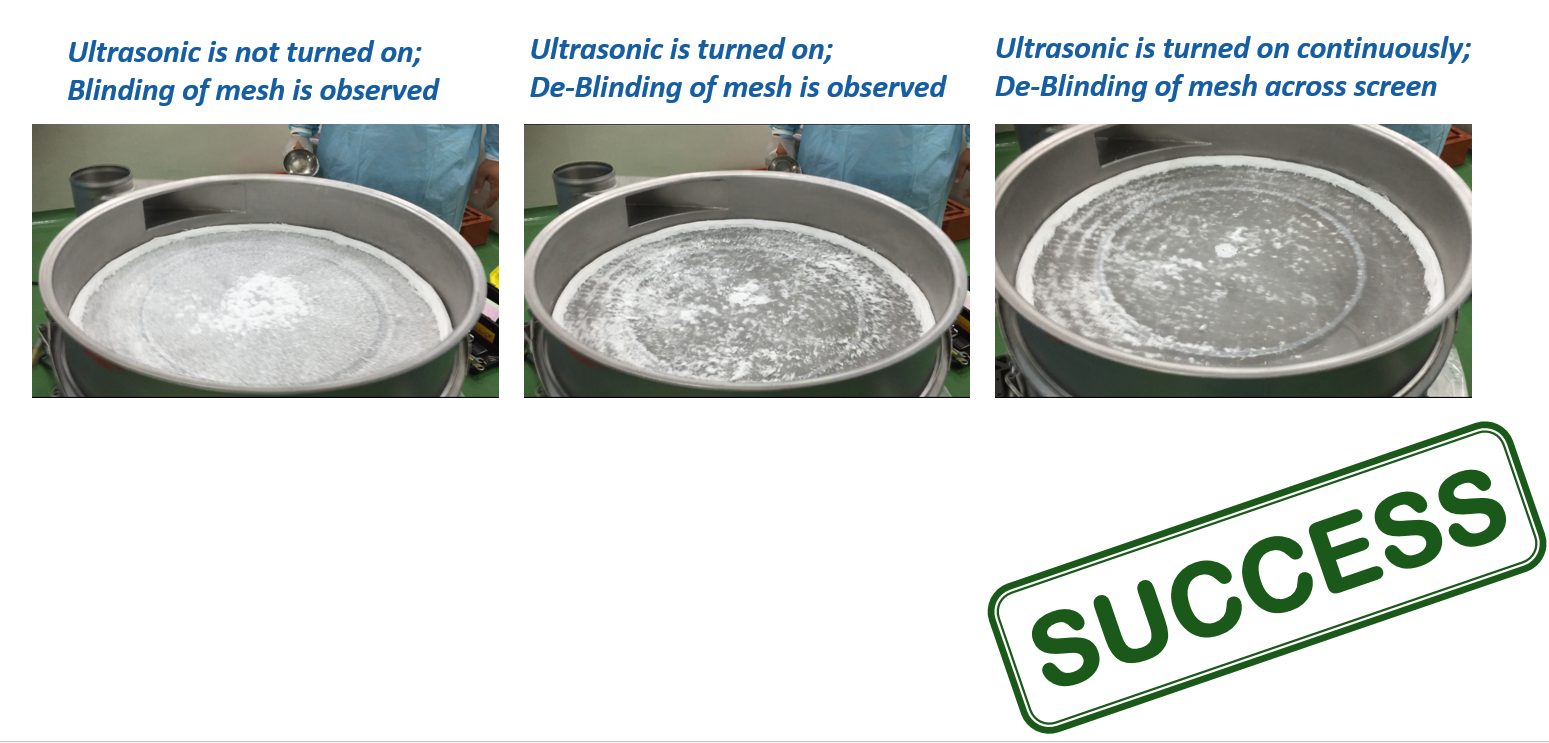

Prevention of Mesh Blinding with TAPIS TEKNIK Ultrasonic Screening System

The TAPIS TEKNIK Ultrasonic setup prevents mesh blinding, pushing performance levels and production line efficiency to a much higher level, improving the quality of final products and also enhance the processing needs of end-user.

The TAPIS Ultrasonic Screen has changed the scenario of screening difficult materials such as those having the characteristics of being light and sticky. Electrostatic powder paint, stainless steel powder, iron powder, manganese sulphide or powder such as tungsten carbide are commonly sieved using Ultrasonic.

Through the usage of ultrasonic de-binding, TAPIS TEKNIK has successfully assist clients to go into the strategy of using “clean-energy” to achieve higher output.

Gone are the days where FDA silicon balls and sliders are used extensively to achieve this effect. The new generation of Ultrasonics ensure that the issue of sliders getting “shorter” in height or silicon balls breaking into pieces are resolved.

Prevention of mesh blinding reduces the loss of good product. The ultrasonic capability screens powder in a single pass, maximizing screening capacity. The hassle of re-screening or re-work can be reduced or minimized. This saves the end-user from unnecessary downtime and also help in increasing production output and product quality.

We are able to implement similar ultrasonic concepts into machines that are not of TAPIS brand as well. Please Contact Us for more info.